Low Impact Verification: We LOVE LIV!

Utility designation and mark-out services are a cost-effective means of identifying potential conflicts with existing underground infrastructure, objects or utilities that need to be avoided during the excavation process. But how a locate is literally “marked-out” can make a big difference.

Some states have established policies around the concept of “low impact markings” that provide guidance for excavators on how to call in a ticket and for utilities responding to the ticket. According to Sunshine 811, the One Call service for Florida, “Whether requesting a new locate ticket or renewing an existing ticket, excavators are required to follow low impact marking practices. This begins with the locate description on your ticket.

The practices […] serve four purposes:

- Helps ensure the locate is accurate

- Reduces unnecessary locate marks

- Reduces the amount of time locate marks are refreshed

- Reduces time for the locator

We couldn’t agree more!

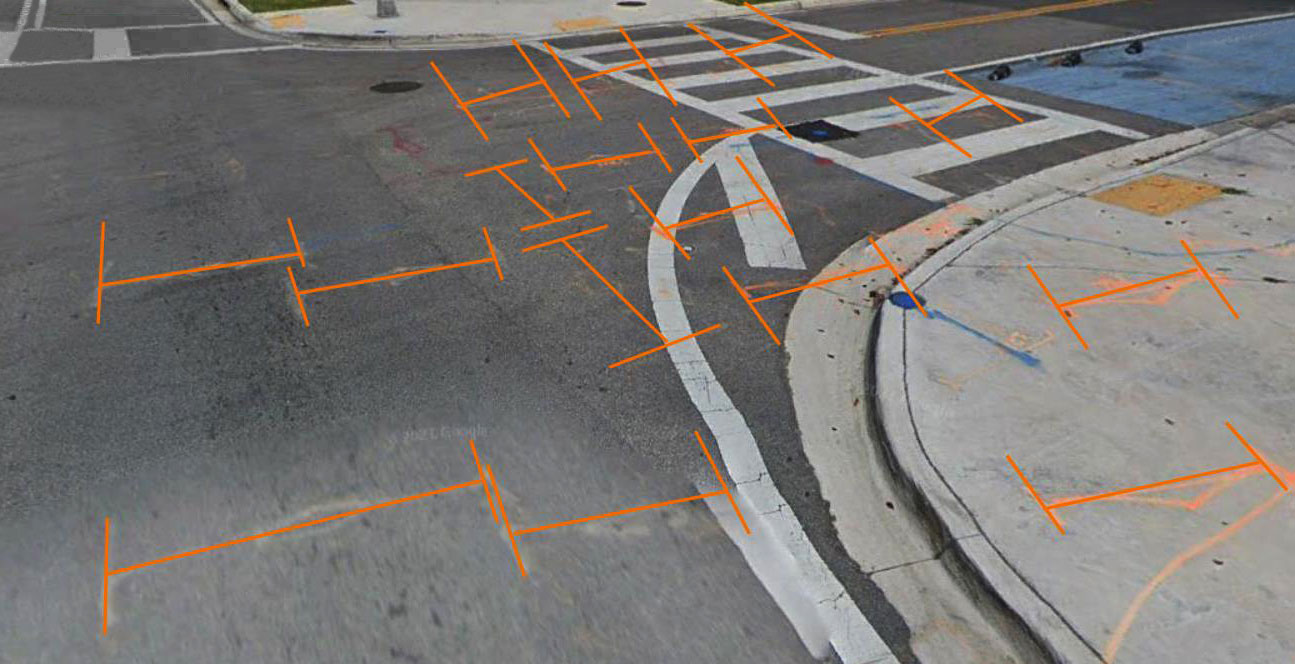

Excessive Mark-outs

First, let’s begin with a mark-out observation that our technicians at Colliers Engineering & Design have encountered in the field. With millions of miles of buried utilities located beneath the surface of the earth and an abundance of new underground infrastructure being installed every day, that adds up to a lot of utilities. 811 One Call mark-outs are performed using electromagnetic detection which is a good first step. However, when a field technician uses excessive paint lines to mark-out a utility corridor, by adding more than what is standard,

First, let’s begin with a mark-out observation that our technicians at Colliers Engineering & Design have encountered in the field. With millions of miles of buried utilities located beneath the surface of the earth and an abundance of new underground infrastructure being installed every day, that adds up to a lot of utilities. 811 One Call mark-outs are performed using electromagnetic detection which is a good first step. However, when a field technician uses excessive paint lines to mark-out a utility corridor, by adding more than what is standard,

it can hinder an excavation operation. Especially in urban sites with a high density of utilities.

Here’s Why

Let’s say the contractor is performing a utility tie-in, in a congested urban setting. The site still has to be marked-out for all utilities. Assuming there could be up to 18 utilities under one location, and you’re only looking for the water line, you can see how excessive mark-outs are compounded by extreme marking. While it’s understood that the tolerance on each side of the utility corridor is 24”, if the tolerance is also marked-out, it can become confusing when combined with all the other mark-outs, turning the site into a sea of paint lines. For example, if you have a 5ft utility corridor with a 24” tolerance on each side, the excavator will need to dig a 9ft-wide trench. This work requires the contractor to hand-dig the site which increases the probability of injury as well as getting confused by excessive mark-outs which adds to the project timeline. Also in the mix is that if the contractor damages the utility, they’re responsible.

Meet SUE

So, now that you’ve seen the importance of Low Impact Marking, we’ve taken that concept a step further by performing Low Impact Verification, or LIV as we like to call it. By using the subsurface utility engineering, or SUE, we can perform a highly accurate, less invasive, utility investigation once the 811 mark-out is complete. SUE is a process that follows a series of quality levels for gathering information about a utility. This begins with utility record research and ends with the highest level of accuracy by using nondestructive methods to physically locate, designate and verify a utility. This is done by digging test holes and exposing the utility using a vacuum excavation process which allows technicians to document and confirm horizontal and vertical location as well as other characteristics including condition, size and material.

Using Low Impact Verification:

- Reduces excessive utility locate marks

- Provides a clear and accurate locate mark of depicted utility

- Provides a safe work zone for contractors

- Creates a less congested excavation path for excavators

- Saves $$$$ due to lost time trying to excavate in areas of excessive marking

- Increases FLM (Field Labor Margins) as less field time is needed to complete a project

- Increases profits, bottom lines to increase likelihood of completing projects on time

- Provides accurate, digitized, utility location mapping for future use

- Less invasive provides shorter timelines

SUE is especially performed on larger sites with a higher density of known existing utilities and/or new construction where the contractor needs an accurate accounting of every utility across the entire site. Particularly if they will be adding or relocating utilities.

Then, there are other situations when only one utility needs to be verified in a condensed area of a project to clear the site for the contractor. This is where LIV is especially effective. With LIV,

we can confirm the accuracy of the 811 mark-outs with SUE for the contractor who may only need a mini excavation in an area that really counts. This data information is then passed back to One Call for future locates.

Overall, the benefits of SUE and LIV are that they give the contractor an accurate location of existing underground utilities while creating create a less congested excavation path for excavators. This helps contractors to make more informed decisions, especially during the design phase; reduces schedule delays and change orders; minimizes excavation risks while increasing site worker safety; and provides full geo-referenced mapping, to suit any budget.

Although studies have been performed on weighing and validating the ROI of a SUE investigation prior to site excavation, contractors and designers still have misconceptions about this important process. Ultimately, keeping your jobsite safe while putting this level of information into the hands of those who need it the most is invaluable!